Soil Remediation Technologies

Some recently asked about my experience with soil remediation technologies. Actually it is very little. I only faced one case when we had big deviation and we had to to ask for actions. And a specialized company has been appointed to the task. Of course I have been involved in monitoring the process. Anyway, this is all the knowledge I have at this moment. If You need details just drop me a line.

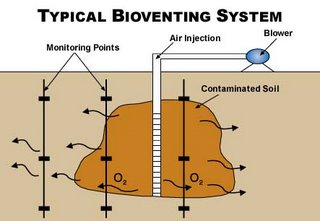

Bioventing – Injecting oxygen into the ground in order to improve aerobic

biodegradation of contaminants. This is a long term cleanup option lasting from several

months to years. Bioventing is an experimental and innovative technology being

investigated and is used at several cleanup sites.

Purpose: Destruction aid

Pros: Successfully used to improve the remediation of soils contaminated with organic

compounds

Cons: May not improve degradation of chlorinated compounds

In situ/ex situ: In-situ

Contaminants remediated: BTEX compounds, nonhalogenated VOCs, some pesticides,

and wood preservatives

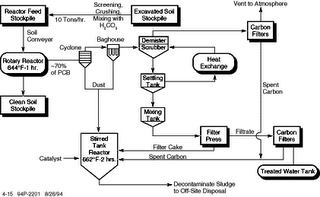

Dehalogenation - The use of chemicals to remove halogens (chlorine, bromine, etc.)

from contaminants. The by-product of dehalogenation is a non-toxic salt, partial

volatilization or decomposition of the contaminant. This is a short to medium term

method of remediation.

Purpose: Contaminant destruction/transformation

Pros: Good for low volume and low concentration contamination, successful in treating

PCB’s

Cons: May not be cost-effective for large treatment volumes, high clay and moisture

content increase costs. Requires air emission equipment and other treatment equipment

In situ/ex situ: Ex situ

Contaminants remediated: VOCs, SVOCs

Fluid/vapor extraction - Liquid and gas are removed from the ground using a high

vacuum system in extraction wells. Treatment of the removed contaminants is required.

Purpose: Removal

Pros: May shorten cleanup time at sites with VOC and fuel contamination

Cons: May not work well at heterogeneous sites, water and vapor must be treated

In situ/ex situ: Ex situ

Contaminants remediated: VOCs, some SVOCs

Geotechnical Systems- use of building foundations, storage facilities, etc. to minimize

exposure to contaminants and prevent rainwater from entering the wastes and creating

leachate. The building acts as a cap.

Purpose: Containment

Pros: Reduced remediation costs (separate remediation processes are not required, the

structure provides the containment)

Cons: Does not reduce contaminant volume, toxicity or mobility, if groundwater is

contaminated vertical walls may be required increasing costs

In situ/ex situ: In situ

Contaminants remediated: All

Incineration – Burning wastes in order to destroy contaminants by volatilization and

combustion.

Purpose: Contaminant destruction

Pros: Proven technology, destroys large number of contaminants

Cons: Only one off-site incinerator approved for PCB and dioxin, potential transportation

costs, bottom ash may require stabilization if heavy metals are incinerated, requires

excavation, additional treatment may be required for soils with volatile metals

In situ/ex situ: Ex situ

Contaminants remediated: VOCs, SVOCs, fuels and explosives

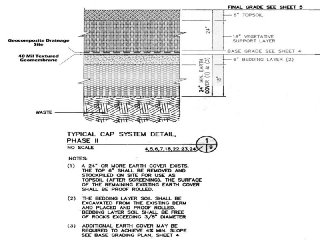

Landfill Cap/Brownfields Cap - a covering over a site that minimizes exposure to

contaminants and prevents rainwater from entering the wastes and creating leachate.

There are 3 major types of landfill caps. A RCRA Subtitle C landfill cap is for hazardous

waste landfills, a RCRA Subtitle D landfill cap is used on sanitary landfills. The last type

of cap is an asphalt, concrete, or topsoil cap.

biodegradation of contaminants. This is a long term cleanup option lasting from several

months to years. Bioventing is an experimental and innovative technology being

investigated and is used at several cleanup sites.

Purpose: Destruction aid

Pros: Successfully used to improve the remediation of soils contaminated with organic

compounds

Cons: May not improve degradation of chlorinated compounds

In situ/ex situ: In-situ

Contaminants remediated: BTEX compounds, nonhalogenated VOCs, some pesticides,

and wood preservatives

Dehalogenation - The use of chemicals to remove halogens (chlorine, bromine, etc.)

from contaminants. The by-product of dehalogenation is a non-toxic salt, partial

volatilization or decomposition of the contaminant. This is a short to medium term

method of remediation.

Purpose: Contaminant destruction/transformation

Pros: Good for low volume and low concentration contamination, successful in treating

PCB’s

Cons: May not be cost-effective for large treatment volumes, high clay and moisture

content increase costs. Requires air emission equipment and other treatment equipment

In situ/ex situ: Ex situ

Contaminants remediated: VOCs, SVOCs

Fluid/vapor extraction - Liquid and gas are removed from the ground using a high

vacuum system in extraction wells. Treatment of the removed contaminants is required.

Purpose: Removal

Pros: May shorten cleanup time at sites with VOC and fuel contamination

Cons: May not work well at heterogeneous sites, water and vapor must be treated

In situ/ex situ: Ex situ

Contaminants remediated: VOCs, some SVOCs

Geotechnical Systems- use of building foundations, storage facilities, etc. to minimize

exposure to contaminants and prevent rainwater from entering the wastes and creating

leachate. The building acts as a cap.

Purpose: Containment

Pros: Reduced remediation costs (separate remediation processes are not required, the

structure provides the containment)

Cons: Does not reduce contaminant volume, toxicity or mobility, if groundwater is

contaminated vertical walls may be required increasing costs

In situ/ex situ: In situ

Contaminants remediated: All

Incineration – Burning wastes in order to destroy contaminants by volatilization and

combustion.

Purpose: Contaminant destruction

Pros: Proven technology, destroys large number of contaminants

Cons: Only one off-site incinerator approved for PCB and dioxin, potential transportation

costs, bottom ash may require stabilization if heavy metals are incinerated, requires

excavation, additional treatment may be required for soils with volatile metals

In situ/ex situ: Ex situ

Contaminants remediated: VOCs, SVOCs, fuels and explosives

Landfill Cap/Brownfields Cap - a covering over a site that minimizes exposure to

contaminants and prevents rainwater from entering the wastes and creating leachate.

There are 3 major types of landfill caps. A RCRA Subtitle C landfill cap is for hazardous

waste landfills, a RCRA Subtitle D landfill cap is used on sanitary landfills. The last type

of cap is an asphalt, concrete, or topsoil cap.

Purpose: Containment

Pros: Asphalt/concrete cap is low cost, been approved at numerous sites

Cons: Does not reduce contaminant volume, toxicity or mobility, if groundwater is

contaminated vertical walls may be required increasing costs, cap may develop leaks over

time

In situ/ex situ: In situ

Contaminants remediated: All

Natural Attenuation (IT) – Allows nature to reduce or remove the level of contaminants

in the ground. Some examples of natural attenuation are biodegradation, dilution,

dispersion or adsorption in the soil. When analyzing this method for use exposure

pathways and property use must be looked at closely.

Purpose: Contaminant destruction, dilution and/or containment

Pros: Low maintenance, low cost

Cons: Typically a slow process, long term monitoring of the site required, may require

extensive site characterization

In situ/ex situ: In situ

Contaminants remediated: Some VOCs, BTEX compounds

Off-site disposal – Soil is excavated and transported to an off-site disposal location

which meets regulatory requirements for hazardous waste disposal. The waste may

require pre-treatment prior to acceptance by the disposal site.

Purpose: Containment

Pros: Proven method, relatively cheap

Cons: Cost may increase due to shipping to a permitted facility, regulatory agencies

prefer treatment, waste may require treatment prior to disposal

In situ/ex situ: Ex situ

Contaminants remediated: All

Pros: Asphalt/concrete cap is low cost, been approved at numerous sites

Cons: Does not reduce contaminant volume, toxicity or mobility, if groundwater is

contaminated vertical walls may be required increasing costs, cap may develop leaks over

time

In situ/ex situ: In situ

Contaminants remediated: All

Natural Attenuation (IT) – Allows nature to reduce or remove the level of contaminants

in the ground. Some examples of natural attenuation are biodegradation, dilution,

dispersion or adsorption in the soil. When analyzing this method for use exposure

pathways and property use must be looked at closely.

Purpose: Contaminant destruction, dilution and/or containment

Pros: Low maintenance, low cost

Cons: Typically a slow process, long term monitoring of the site required, may require

extensive site characterization

In situ/ex situ: In situ

Contaminants remediated: Some VOCs, BTEX compounds

Off-site disposal – Soil is excavated and transported to an off-site disposal location

which meets regulatory requirements for hazardous waste disposal. The waste may

require pre-treatment prior to acceptance by the disposal site.

Purpose: Containment

Pros: Proven method, relatively cheap

Cons: Cost may increase due to shipping to a permitted facility, regulatory agencies

prefer treatment, waste may require treatment prior to disposal

In situ/ex situ: Ex situ

Contaminants remediated: All

Soil Vapor Extraction (SVE) – A method of removing volatile and some semivolatile

organic contaminants from nonsaturated soil (vadose zone) by applying a vacuum to the

soil through extraction wells. The contaminants are removed from the ground to undergo

further treatment.

Purpose: Remove contaminants from the ground

Pros: Presumptive or generic remedy, relatively inexpensive, may increase

bioremediation when used in conjunction with air sparging, no excavation required,

highly effective in VOC removal

Cons: Treatment time slows in heterogeneous soils, heating the soil and air sparging may

be required, need to control air emissions

In situ/ex situ: In situ

Contaminants remediated: VOCs, some SVOCs

Soil Flushing – A process where a solution is injected in the ground in order to move

the contaminants to an area where they may be extracted from the ground and treated.

This is a developing technology which so far has seen limited success.

Purpose: Aid in making contaminants readily accessible for treatment

Pros: Portable technology, excavation not required

Cons: Limited success, groundwater flow must be understood completely to prevent

spreading contamination further

In situ/ex situ: In situ

Contaminants remediated: VOCs, SVOCs, some metals, fuels, pesticides

organic contaminants from nonsaturated soil (vadose zone) by applying a vacuum to the

soil through extraction wells. The contaminants are removed from the ground to undergo

further treatment.

Purpose: Remove contaminants from the ground

Pros: Presumptive or generic remedy, relatively inexpensive, may increase

bioremediation when used in conjunction with air sparging, no excavation required,

highly effective in VOC removal

Cons: Treatment time slows in heterogeneous soils, heating the soil and air sparging may

be required, need to control air emissions

In situ/ex situ: In situ

Contaminants remediated: VOCs, some SVOCs

Soil Flushing – A process where a solution is injected in the ground in order to move

the contaminants to an area where they may be extracted from the ground and treated.

This is a developing technology which so far has seen limited success.

Purpose: Aid in making contaminants readily accessible for treatment

Pros: Portable technology, excavation not required

Cons: Limited success, groundwater flow must be understood completely to prevent

spreading contamination further

In situ/ex situ: In situ

Contaminants remediated: VOCs, SVOCs, some metals, fuels, pesticides

Thermal desorption – Contaminants with low boiling points are vaporized by heating

wastes to moderate temperatures. Steam injection, electrical resistance heating and radiofrequency

heating may be used to raise soil temperatures. These temperatures range from

200° to 1000°_F depending on the contaminant to be vaporized. Thermal desorption is

only an aid in contaminant, it is typically used in conjunction with SVE in order to

increase the amount of contaminants removed from the soil.

Purpose: Aid in removing contaminants from the ground

Pros: Steam injection effectively removes petroleum hydrocarbons (BTEX), electrical

heating works well in fine grained soils

Cons: Innovative technology, full recovery of contaminant may be difficult, may not

work well in heterogeneous soils, high moisture content in soil increases costs, requires

treatment of off-gas

In situ/ex situ: Both may be used in situ or ex situ following excavation

Contaminants remediated: SVOCs, PAHs, PCBs and pesticides. May also be effective in

separating organics from coal tar wastes, refinery wastes, wood-treating wastes, paint

wastes and synthetic rubber processing waste.

wastes to moderate temperatures. Steam injection, electrical resistance heating and radiofrequency

heating may be used to raise soil temperatures. These temperatures range from

200° to 1000°_F depending on the contaminant to be vaporized. Thermal desorption is

only an aid in contaminant, it is typically used in conjunction with SVE in order to

increase the amount of contaminants removed from the soil.

Purpose: Aid in removing contaminants from the ground

Pros: Steam injection effectively removes petroleum hydrocarbons (BTEX), electrical

heating works well in fine grained soils

Cons: Innovative technology, full recovery of contaminant may be difficult, may not

work well in heterogeneous soils, high moisture content in soil increases costs, requires

treatment of off-gas

In situ/ex situ: Both may be used in situ or ex situ following excavation

Contaminants remediated: SVOCs, PAHs, PCBs and pesticides. May also be effective in

separating organics from coal tar wastes, refinery wastes, wood-treating wastes, paint

wastes and synthetic rubber processing waste.

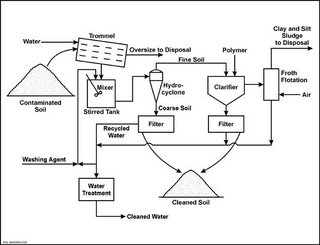

Soil Washing – Soil is excavated and washed with water to remove contaminants.

Additives may be added to the water to enhance contaminant removal. The soil may

have to go through several remediation cycles to remove the contaminant. The wash

water must then undergo treatment to remediate the contaminants. The cleaned soil may

then be used as fill on site.

Purpose: Contaminant removal

Pros: cost effective, can reduce volume of contaminated soil

Cons: washing solution may be difficult to formulate for complex waste mixtures, soil

may require pretreatment, washing fluid requires treatment, organics may be difficult to

remove from clay-size particles

In situ/ex situ: Ex-situ

Contaminants removed: SVOC, fuels, heavy metals

Additives may be added to the water to enhance contaminant removal. The soil may

have to go through several remediation cycles to remove the contaminant. The wash

water must then undergo treatment to remediate the contaminants. The cleaned soil may

then be used as fill on site.

Purpose: Contaminant removal

Pros: cost effective, can reduce volume of contaminated soil

Cons: washing solution may be difficult to formulate for complex waste mixtures, soil

may require pretreatment, washing fluid requires treatment, organics may be difficult to

remove from clay-size particles

In situ/ex situ: Ex-situ

Contaminants removed: SVOC, fuels, heavy metals

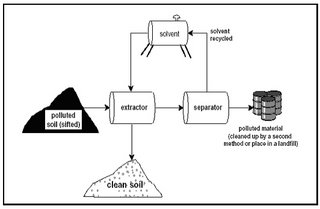

Solvent extraction (IT) – Soil is excavated, screened to remove rocks and debris, and

then added to an extraction unit. In the extraction unit a solvent is added to the soil in

order to remove organic contaminants and segregate the different fractions (ie. water, oil

and soil layers). The mixture of water, solids, and solvent absorb different contaminants.

Each fraction is then separated and processed in order to remediate the contaminants that

collect in them.

Purpose: Contaminant removal

Pros: Reduces waste volume, operates without air emissions equipment

Cons: Inorganic contaminants may affect removal of solvents, systems may be complex

increasing engineering costs, extensive pretreatment of soil may be required

In situ/ex situ: Ex situ

Contaminants removed: organic contaminants from paint wastes, synthetic rubber

process wastes, coal tar wastes, drilling muds, wood treating wastes, pesticide/insecticide

wastes, and oily wastes

Stabilization/Solidification - Using cement, concrete, chemical fixation, etc to stabilize

or physically bind contaminants. The solid mass limits the solubility or mobility of the

contaminants though it doesn't destroy them.

Purpose: Containment

Pros: Relatively cheap, established vendor base,

Cons: Some processes may increase waste volume, solidified material may affect future

site use, depth of contamination may affect options

In situ/ex situ: Both

Contaminants remediated: Metals, radionuclides

then added to an extraction unit. In the extraction unit a solvent is added to the soil in

order to remove organic contaminants and segregate the different fractions (ie. water, oil

and soil layers). The mixture of water, solids, and solvent absorb different contaminants.

Each fraction is then separated and processed in order to remediate the contaminants that

collect in them.

Purpose: Contaminant removal

Pros: Reduces waste volume, operates without air emissions equipment

Cons: Inorganic contaminants may affect removal of solvents, systems may be complex

increasing engineering costs, extensive pretreatment of soil may be required

In situ/ex situ: Ex situ

Contaminants removed: organic contaminants from paint wastes, synthetic rubber

process wastes, coal tar wastes, drilling muds, wood treating wastes, pesticide/insecticide

wastes, and oily wastes

Stabilization/Solidification - Using cement, concrete, chemical fixation, etc to stabilize

or physically bind contaminants. The solid mass limits the solubility or mobility of the

contaminants though it doesn't destroy them.

Purpose: Containment

Pros: Relatively cheap, established vendor base,

Cons: Some processes may increase waste volume, solidified material may affect future

site use, depth of contamination may affect options

In situ/ex situ: Both

Contaminants remediated: Metals, radionuclides

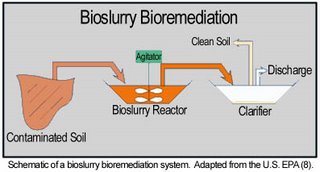

Biodegradation or Bioremediation – Breaking down of contaminants by fungi, bacteria,

and other microbes. The microbes use the contaminants as food, typically producing

carbon dioxide, water and cells as the byproducts of the degradation. Some contaminants

may only be partially degraded to another substance. These substances may be more

toxic than the original contaminant in some cases. The microbes may be introduced into

the ground or may be native organisms.

Purpose: Contaminant degradation

Pros: Low maintenance, destroys contaminants, utilizes natural processes

Cons: Organism growth dependent on many factors, toxic by-products may be produced

In situ/ex situ: Both

Contaminants remediated: Fuels, VOCs, SVOCs

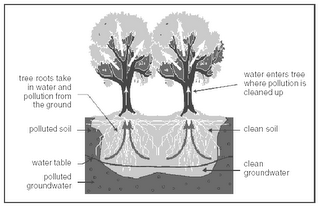

Phytoremediation (IT) – Plants and trees are used to remove contaminants from the

ground in phytoremediation. This may be accomplished by the uptake of the

contaminants by plants and trees which is called phytoextraction. Rhizofiltration

involves plants grown in a greenhouse using contaminated water as a water source. The

plants perform phytoextraction in a greenhouse rather than onsite. Phytodegradation

breaks down organic contaminants by enzymes which are secreted by the plants.

Phytovolatilization may occur where contaminants pass through the plant and evaporate

to the atmosphere.

Purpose: contaminant destruction, containment,

Pros: Plants and trees look nice, relatively cheap

Cons: Works at shallow depths (root depth), contaminants may collect in leaves

In situ/ex situ: In situ

Contaminants remediated: Fuels, VOCs, SVOCs, metals

and other microbes. The microbes use the contaminants as food, typically producing

carbon dioxide, water and cells as the byproducts of the degradation. Some contaminants

may only be partially degraded to another substance. These substances may be more

toxic than the original contaminant in some cases. The microbes may be introduced into

the ground or may be native organisms.

Purpose: Contaminant degradation

Pros: Low maintenance, destroys contaminants, utilizes natural processes

Cons: Organism growth dependent on many factors, toxic by-products may be produced

In situ/ex situ: Both

Contaminants remediated: Fuels, VOCs, SVOCs

Phytoremediation (IT) – Plants and trees are used to remove contaminants from the

ground in phytoremediation. This may be accomplished by the uptake of the

contaminants by plants and trees which is called phytoextraction. Rhizofiltration

involves plants grown in a greenhouse using contaminated water as a water source. The

plants perform phytoextraction in a greenhouse rather than onsite. Phytodegradation

breaks down organic contaminants by enzymes which are secreted by the plants.

Phytovolatilization may occur where contaminants pass through the plant and evaporate

to the atmosphere.

Purpose: contaminant destruction, containment,

Pros: Plants and trees look nice, relatively cheap

Cons: Works at shallow depths (root depth), contaminants may collect in leaves

In situ/ex situ: In situ

Contaminants remediated: Fuels, VOCs, SVOCs, metals

0 Comments:

Post a Comment

<< Home